If you’re searching for a trusted high mast pole manufacturer, understanding the difference between ordinary suppliers and industry-leading manufacturers can save you time, money, and headaches. High mast poles are critical for stadiums, highways, ports, airports, and industrial complexes. Choosing the right manufacturer ensures safety, durability, and optimal lighting performance.

Why the Right Manufacturer Makes All the Difference

High Mast Pole Manufacturer Common Pitfalls When Selecting a Supplier

Many projects fail due to choosing suppliers who focus only on price rather than quality. Common mistakes include:

- Ignoring material quality and thickness.

- Overlooking wind load and structural design.

- Skipping certifications and compliance checks.

- Lack of maintenance-friendly design such as lowering mechanisms.

The Impact of Manufacturing Quality on Long-Term ROI

A reliable manufacturer ensures robust steel fabrication, precise galvanisation, and rigorous testing. While initial costs may be higher, high-quality poles reduce long-term maintenance, replacements, and downtime.

What Defines a Great High Mast Pole Manufacturer in India

High Mast Pole Manufacturer Process: From Steel to Pole

Triveni Solar’s end-to-end manufacturing process includes:

- Material Selection: Premium mild steel for strength and durability.

- Fabrication: Custom heights (12 m–45 m), octagonal/polygonal/conical shapes.

- Hot-Dip Galvanization: Protects against corrosion, ensures longevity.

- Quality Testing: Wind load, structural stress, coating adherence.

- Packaging & Dispatch: Safe transport to project sites.

High Mast Pole Manufacturer Critical Technical Specs (Height, Wind Load, Material, Finish)

Key specifications buyers should verify include:

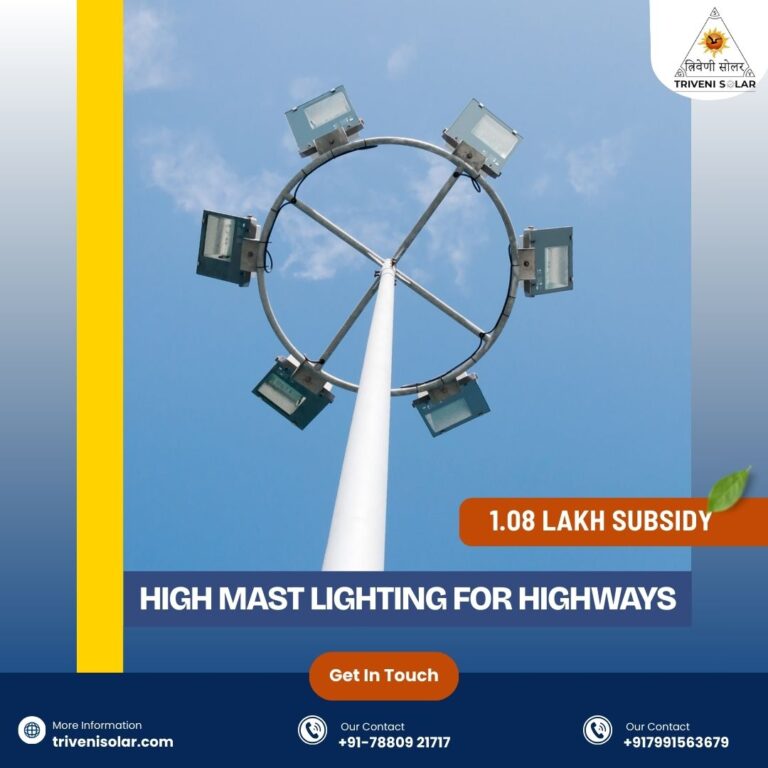

- Height: 12 m to 45 m for stadiums, highways, and industrial parks.

- Wind Load Rating: Designed for local zone (IS 875 Part 3).

- Material: Hot-dip galvanized mild steel with optional powder coating.

- Finish: Smooth, corrosion-resistant surface with extended life.

- Lowering Mechanism: Safety and maintenance convenience.

High Mast Pole Manufacturer Certifications, Standards & Compliance

Always verify ISO/BIS certifications and adherence to Indian and international standards. Triveni Solar ensures all poles comply with IS 6533 and IS 875 standards for wind load and structural integrity.

What to Look For: Buyer’s Checklist & Comparative Data Table

Visual Comparison of Pole Heights & Applications

| Height (m) | Typical Application | Recommended Lighting |

|---|---|---|

| 12–18 | Small industrial yards, warehouses | LED floodlights, 4–6 fixtures |

| 20–30 | Highways, stadiums, ports | LED floodlights, 6–12 fixtures |

| 35–45 | Large stadiums, airports, major industrial zones | LED floodlights, 12–16 fixtures |

Cost vs Maintenance: Hot-Dip Galvanised vs Painted Finish

| Finish | Initial Cost | Maintenance Frequency | Lifespan |

|---|---|---|---|

| Hot-Dip Galvanised | Medium | Low | 20–25 years |

| Painted | Low | High | 8–12 years |

Innovation & Future Trends from Top High Mast Pole Manufacturer

Smart Lighting Integration (IoT, Sensors)

Modern high mast poles now include IoT-enabled lighting, motion sensors, and automated dimming. This reduces energy consumption and allows remote monitoring for maintenance efficiency.

Solar High Mast Poles & Sustainability

Triveni Solar integrates solar panels with high mast poles for off-grid lighting solutions. Benefits include:

- Reduced electricity costs.

- Eco-friendly, low carbon footprint.

- Reliable operation during grid failures.

Case Study: Real-World Project by Triveni Solar

Project Overview & Challenges

Client: Major Industrial Park in Maharashtra

Requirement: 30 high mast poles (30 m) for large area lighting, withstanding wind speed of 180 km/h.

Solution Delivered & Results Achieved

- Custom octagonal poles fabricated with a hot-dip galvanized finish.

- LED smart lighting integration for energy efficiency.

- Project completed on time with zero safety incidents.

- ROI achieved within 3 years due to low maintenance and energy savings.

FAQs: Everything You Must Ask Your High Mast Pole Manufacturer

1. What height ranges are available for high mast poles?

High mast poles typically range from 12m to 45 m, depending on application and area coverage requirements.

2. Why choose hot-dip galvanized poles over painted finish?

Hot-dip galvanisation provides superior corrosion resistance, lower maintenance, and longer lifespan compared to painted poles.

3. Can high mast poles support smart lighting systems?

Yes, modern poles can integrate IoT, sensors, and automated lighting systems for energy efficiency and remote monitoring.

4. What standards should high mast poles comply with in India?

Ensure poles meet IS 6533 for steel structures and IS 875 for wind load design. Certifications such as ISO and BIS are recommended.

5. Do you provide installation and maintenance services?

Reputable manufacturers like Triveni Solar offer turnkey solutions including installation, commissioning, and maintenance support.

Conclusion & Next Steps

Choosing the right high mast pole manufacturer is critical for safety, durability, and efficiency. Triveni Solar delivers turnkey solutions from fabrication to smart lighting integration, ensuring your large-area lighting projects succeed effortlessly.

Ready to upgrade your lighting infrastructure? Contact Triveni Solar today:

📞 +91 79915 63679 | +91 78809 21717

💻 Visit trivenisolar.com to explore our full range of high mast poles and project solutions.