Discover the unmatched durability and reliability of hot-dip galvanized solar structures with Triveni Solar. Designed to withstand extreme weather conditions, our structures ensure longevity and efficiency for any solar project, crucial for developers in India seeking sustainable and certified solutions.

Table of Contents

- What Makes Hot Dip Galvanized Solar Structures Unique?

- Benefits for Developers in India

- Choosing the Right Manufacturer

- Understanding the Galvanization Process

- Current Trends in Solar Infrastructure

- FAQs

- Research Insights on Solar Structures

- Conclusion: Reliable Solar Solutions

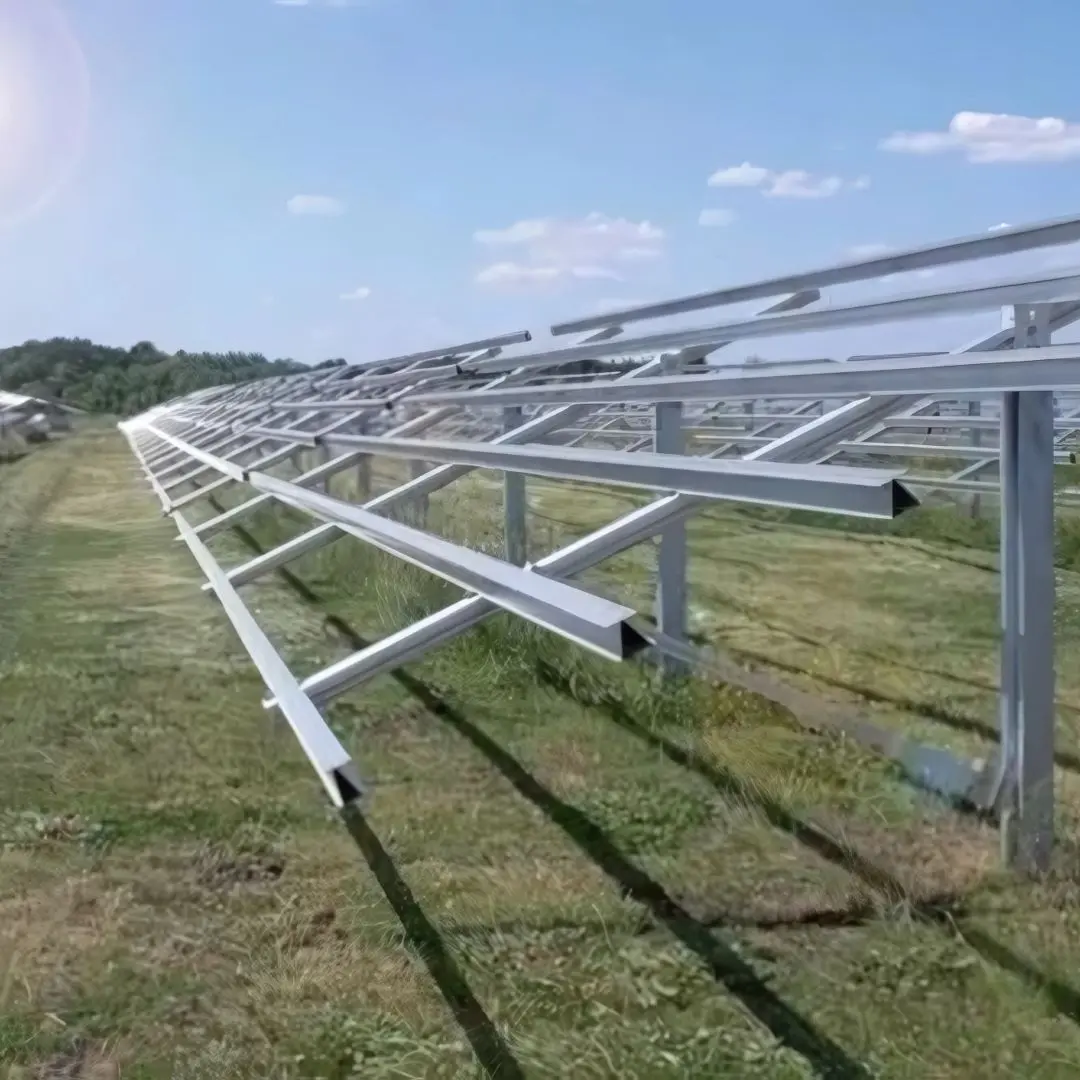

What Makes Hot-Dip Galvanized Solar Structures Unique?

Hot dip galvanized solar structures are renowned for their exceptional protection against corrosion, making them ideal for diverse environmental conditions. This protective layer is crucial for enhancing the lifespan and strength of solar installations, thereby optimizing performance and investment returns. Learn more about our galvanized solar mounting structures.

Technical Advantages

- Improved Resistance: The zinc coating offers exceptional resistance to environmental hazards, ensuring the metal beneath remains unscathed.

- Maintenance-Free: Once dipped, these structures require minimal maintenance, translating to lower long-term costs.

- Longevity: With a life expectancy surpassing 50 years in rural environments, these structures promise lasting reliability.

Solar Structures Benefits for Developers in India

As India steadily prioritizes renewable energy, hot-dip galvanized solar structures offer indispensable benefits to developers focused on sustainable projects.

Economic Benefits

- Cost-Effectiveness: Reducing maintenance costs while maximizing uptime and productivity.

- Government Incentives: Many governmental solar projects and procurements prefer such durable structures, often qualifying for subsidies and tax benefits.

- Reliable Supply Chain: Partnering with manufacturers like Triveni Solar ensures a consistent and high-quality supply chain.

Environmental Impact

These structures contribute significantly to environmental sustainability. By ensuring renewable energy installations endure, they support India’s ambitious targets to curb carbon emissions and enhance green energy adoption. Check our solar power plant solutions for more insights.

Solar Structures: Choosing the Right Manufacturer

Selecting the right manufacturer is vital to capitalize on the benefits of hot-dip galvanized solar structures. Trustworthy manufacturers adhere to industry standards, provide certifications, and offer comprehensive support.

| Criteria | Importance | Triveni’s Offering |

|---|---|---|

| ISO Certification | Ensures quality and compliance with global standards | ISO 9001 certified for all products |

| Turnkey Solutions | Essential for comprehensive solar project execution | Offers end-to-end solutions from planning to deployment |

| Customization Options | Adapts to specific needs and site conditions | Provides bespoke solutions aligned with client requirements |

Understanding the Galvanization Process

The hot dip galvanization process involves coating steel or iron with zinc at high temperatures. This creates a robust barrier against rust and degradation, essential for maintaining structural integrity in challenging environments.

Process Steps

- Pre-Inspection: Initial check to ensure materials are prepared.

- Cleansing: Removal of impurities and oils through a chemical bath.

- Fluxing: Application of a flux solution to prevent oxidation before dipping.

- Galvanizing: Immersing the material in molten zinc.

- Cooling and Final Inspection: The structure cools, and a final quality check is performed.

Current Trends in Solar Infrastructure

The solar industry is evolving rapidly, and keeping abreast of trends is crucial for developers and manufacturers alike. From technological advancements to policy changes, staying informed ensures strategic alignment with industry shifts.

Trends in Solar Structures

- Modular Designs: Emphasizing flexibility and efficiency, modular setups facilitate easier upgrades and maintenance.

- Advanced Coatings: Beyond zinc, new coatings that resist atmospheric pollutants offer extended longevity.

- Sustainability Goals: Integration with urban planning and sustainable city projects is becoming standardized.

| Year | Solar Capacity Installed (GW) | Growth (%) |

|---|---|---|

| 2025 | 56 | 12% |

| 2026 | 63 | 13% |

FAQs

- What is hot dip galvanization? It’s a process of coating iron or steel with zinc to protect against rust.

- Why choose galvanized steel for solar structures? It offers superior corrosion resistance and longevity.

- How long do these structures last? Typically, they can last over 50 years with minimal maintenance.

- Does Triveni Solar provide customized solutions? Yes, our custom solutions adapt to client needs.

- Are there environmental benefits? Absolutely, as they support sustainable energy projects.

- Can these structures withstand severe weather? Yes, they are engineered to endure extreme climates.

- What certifications does Triveni hold? Triveni holds ISO 9001 certification, among others.

- Why is zinc coating crucial? Zinc acts as a protective and sacrificial layer against corrosion.

- How does galvanization support renewable energy? By ensuring structures last, they optimize the reliability of solar projects.

- What other products does Triveni offer? We offer a range of solar and lighting solutions.

- Is there a warranty? Yes, comprehensive warranties cover most products.

- Where can I get support? Reach out via our contact page.

Research Insights on Solar Structures

A recent study conducted in 2026 highlights the remarkable growth of solar infrastructure in India, with a 13% increase in solar capacity. This surge underscores the critical role that advanced solar structures, like those offered by Triveni Solar, play in facilitating this expansion. Innovations in materials and designs continue to lead the charge towards achieving sustainable energy goals.

Conclusion: Reliable Solar Solutions

Investing in hot dip galvanized solar structures is an intelligent choice for developers seeking durable and reliable solutions. With Triveni Solar, you’re assured of quality, innovation, and unmatched after-sales support. Explore the future of solar energy with our expertly crafted products tailored to meet every specific need. To learn more about our offerings and to start your project today, visit our website.