Certified Galvanized U-Bolts for Industrial Use

Galvanized U‑Bolt Dimensions & Specs

Specifications – Galvanized U‑Bolt

Parameter | Specification |

| Material | Carbon steel, mild steel with galvanized finish (zinc plated or hot‑dip) |

| Thread Size | M6, M10, M12, M16, M20 (inch equivalents available) |

| Pipe Size Compatibility | ½″ to 12″ nominal bore pipes (approx. 15 mm–324 mm OD) |

| Between‑Legs Diameter | From ~28 mm (for ½″) up to ~343 mm (for 12″ standard) |

| U‑Depth (Inside Height) | Standard: ~48–210 mm; Extended: up to ~387 mm |

| Thread Length | Standard: ~30–50 mm; Extended versions up to ~95 mm |

| Tensile/Yield Strength | ~90,000 psi yield / 120,000 psi tensile typical for ≤13″; up to 133,000 psi tensile for larger sizes |

| Finish / Coating | Zinc plating or hot‑dip galvanizing for corrosion resistance |

| Certifications | ISI/BIS compliance possible; ISO/DIN/ANSI standards supported per request |

| Usage Applications | Pipe clamping, structural anchoring, industrial mounting, construction, general use |

Use Cases Across Industries & Projects

Municipal & Government

- Securing street light poles and utility poles

- Mounting signage, traffic and road infrastructure

- Fastening pipes in municipal water supply and sewage systems

- Anchoring elements in PWD infrastructure and bridges

- Securing outdoor catenary and overhead systems commissioning

Commercial & Industrial

- Clamping pipelines and conduits in process plants

- Securing structural beams and steel framing

- Fastening HVAC ducting and mechanical equipment

- Mounting telecom masts and antenna installations

- Assembly of industrial machinery and support brackets

Special Use Case

- Marine and offshore installations exposed to salt air

- Agricultural equipment frames and irrigation pipelines

- Suspension components in transportation and trailer systems

- Cable tray and telecom tower cabling management

- Temporary and modular scaffolding or steel gantry setups

Use Cases Across Industries & Projects

Installation Guide

- Measuring inside diameter and height to match pipe/structural size

- Pre-install alignment & template marking for accurate bolt placement

- Proper torqueing of nuts to specification for load integrity

- Applying anti-seize or lubricant on threads where needed

- Ensuring correct washer and saddle plates installation

Maintenance & Services

- Regular inspection for galvanization wear or corrosion signs

- Re-torque nuts periodically as part of preventive maintenance

- Re-coating or replacing fasteners as required in coastal or wet environments

- Cleaning threaded areas and applying rust-inhibitor sprays

- Access to replacement parts and spares on demand

Warranty & Assurance

- Manufacturer guarantee on galvanized coating and tensile strength

- Certificates of material compliance (e.g. GB / DIN standards)

- Load‑rating documentation for design validation

- ISO 9001/ISO-certified manufacturing and QC processes

- Dedicated customer support and issue resolution channels

Snapshots to Success – Designs, Installations & Innovation

FAQs – What Customers Ask Most !

Your detailed FAQ resource for Galvanized U‑Bolt answers high-intent queries related to performance, sizing, certification, installation, and procurement—trusted information tailored for B2B and institutional buyers seeking secure, durable fastening solutions.

What is a Galvanized U‑Bolt and what is it used for?

What sizes of Galvanized U‑Bolt are available?

How is a Galvanized U‑Bolt measured accurately?

Is the Galvanized U‑Bolt corrosion-resistant for outdoor use?

What load capacity can a Galvanized U‑Bolt support?

Can a Galvanized U‑Bolt meet government tender specifications?

How should a Galvanized U‑Bolt be installed for optimal performance?

How long does the zinc coating on a Galvanized U‑Bolt last?

Are custom sizes or finishes available for a Galvanized U‑Bolt?

Where can I order Galvanized U‑Bolt for bulk or tender projects?

Related Products

Discover related products that complement your needs – durable, efficient, and affordable solutions for lighting, solar, and infrastructure projects.

Foundation Anchor Bolts

Heavy-duty, precision, galvanized, corrosion-resistant, threaded, durable, high-tensile, secure, structural, load-bearing, weatherproof, and engineered.

High Tensile MS Foundation Bolts

High-strength, mild steel, durable, precision-cut, corrosion-resistant, threaded, galvanized, structural-grade, robust, engineered, heavy-duty, and long-lasting.

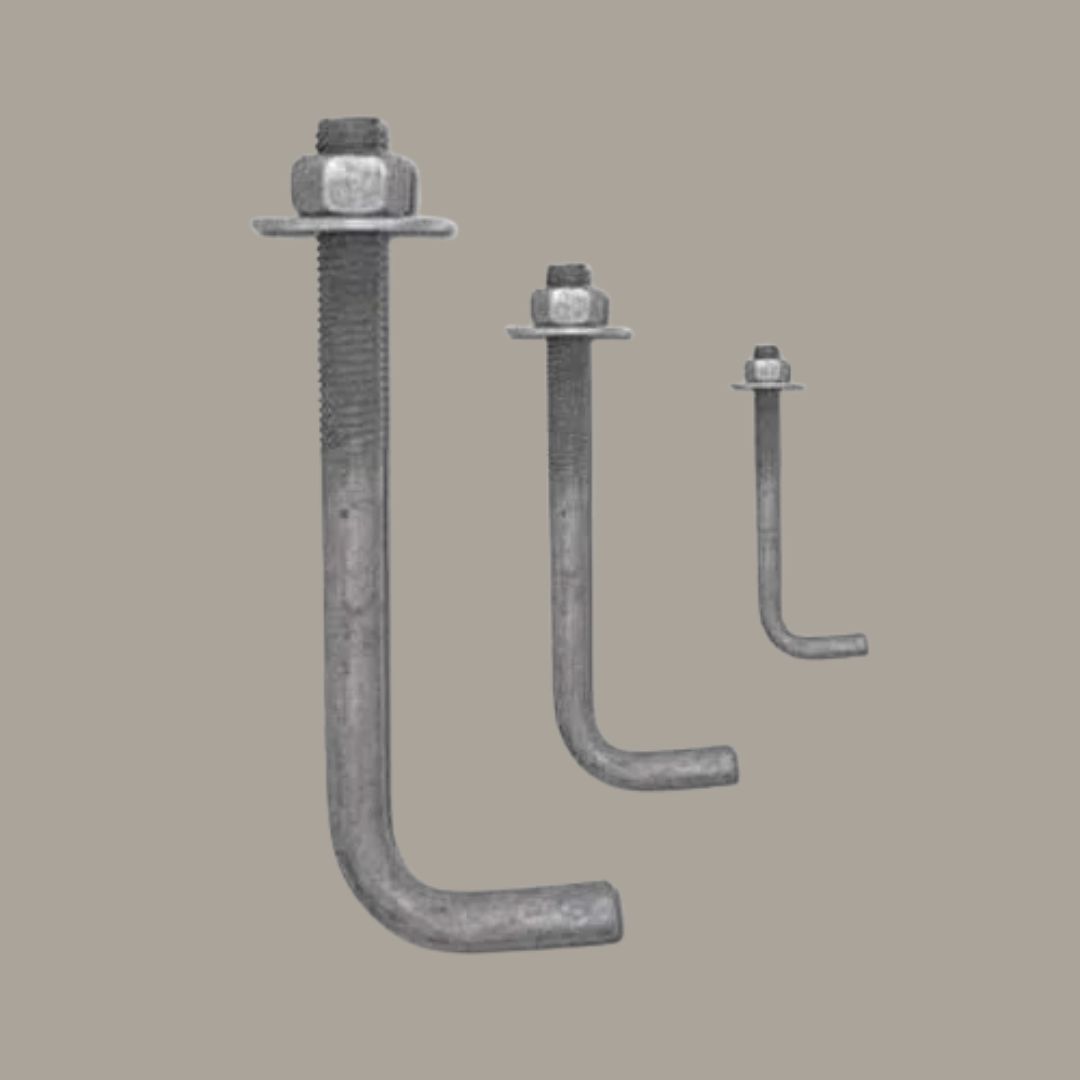

RCC J-Type Anchor Bolts

Concrete-embedded, high-tensile, corrosion-resistant, J-shaped, threaded, precision-engineered, heavy-duty, rustproof, load-bearing, durable, galvanized.