Armoured Cables – Aluminium and Copper Core Options

Durable Armoured Cables with aluminium or copper core for safe, high-performance power transmission. ISI-certified, PWD & ULB-ready. Ideal for industrial, infrastructure, and renewable energy applications. High mechanical protection and weather resistance.

Armoured Cables with Aluminium or Copper Core – ISI Approved

Triveni’s ISI-certified Armoured Cables provide secure, corrosion-resistant power delivery with aluminium or copper cores. Suitable for infrastructure, solar, railways, and heavy industries with high mechanical protection.

Specifications – Armoured Cables (Aluminium/Copper Core)

Parameter | Specification |

|---|---|

| Product Type | Armoured Power Cables |

| Conductor Material | Aluminium / Copper |

| Conductor Size Range | 1.5 sq.mm to 400 sq.mm |

| Voltage Grade | 1.1 kV / 3.3 kV / 6.6 kV |

| Insulation Type | PVC / XLPE |

| Armour Type | GI Wire / GI Strip |

| Outer Sheath | PVC, Black / FR / FRLS |

| Standard | IS 1554 (Part 1), IS 7098 (Part 1) |

| Temperature Range | -10°C to +90°C |

| Application | Underground / Outdoor Electrical Use |

Use Cases Across Industries & Projects

Armoured Cables are ideal for underground, heavy-duty, and exposed applications across government, EPC, solar, and industrial projects. Approved for ULB, PWD, and MNRE procurement. Suits high-stress and corrosive environments.

Municipal & Government

- Street lighting power lines

- Public utility power supply grids

- Smart city and metro rail projects

- Electrification in ULB / PWD zones

- Underground cabling in government complexes

Commercial & Industrial

- Solar power plants

- Factories and industrial substations

- Construction sites and EPC works

- Data centers and telecom towers

- Commercial building electrical wiring

Special Use Case

- Airports and port terminals

- Mining & tunnel lighting

- Flood-prone electrical zones

- Railway and metro cabling systems

- High-altitude & high-humidity zones

Use Cases Across Industries & Projects

Complete support for Armoured Cables — from technical installation to long-term maintenance and warranty. Detailed guides, after-sales service, and PWD/MNRE compliance support included.

Installation Guide

- Load capacity per mm²

- Safety precautions during handling

- Bending radius and torque specifications

- Termination methods for aluminium/copper

- Cable laying diagrams for trench and conduit

Maintenance & Services

- Joint box inspection guidance

- Annual audit checklist for EPCs

- Routine insulation resistance testing

- Inspection of armouring & sheath wear

- Replacement intervals & lifecycle indicators

Warranty & Assurance

- Site failure analysis support

- ISI & BIS compliance guarantee

- On-site inspection during tenders

- OEM documentation & load certification

- 5-year manufacturing defect warranty

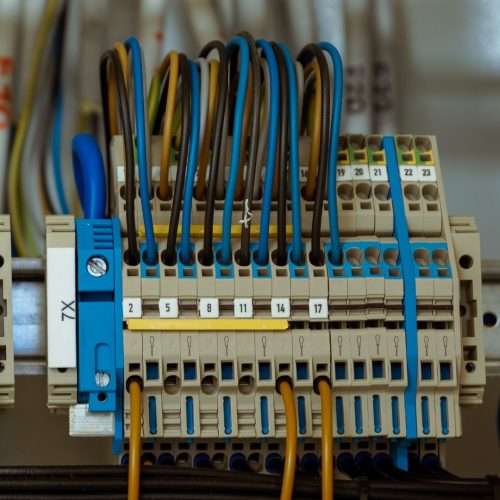

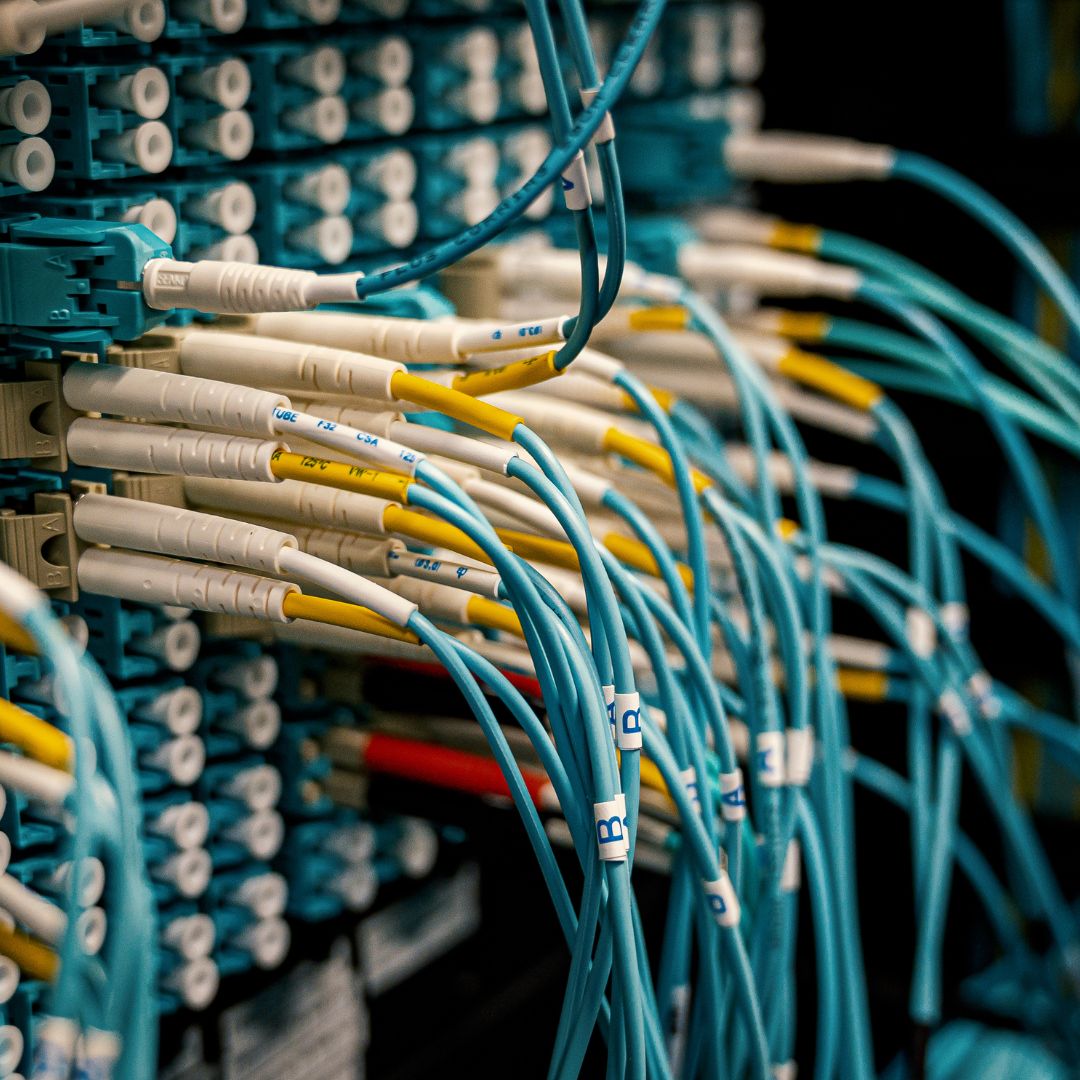

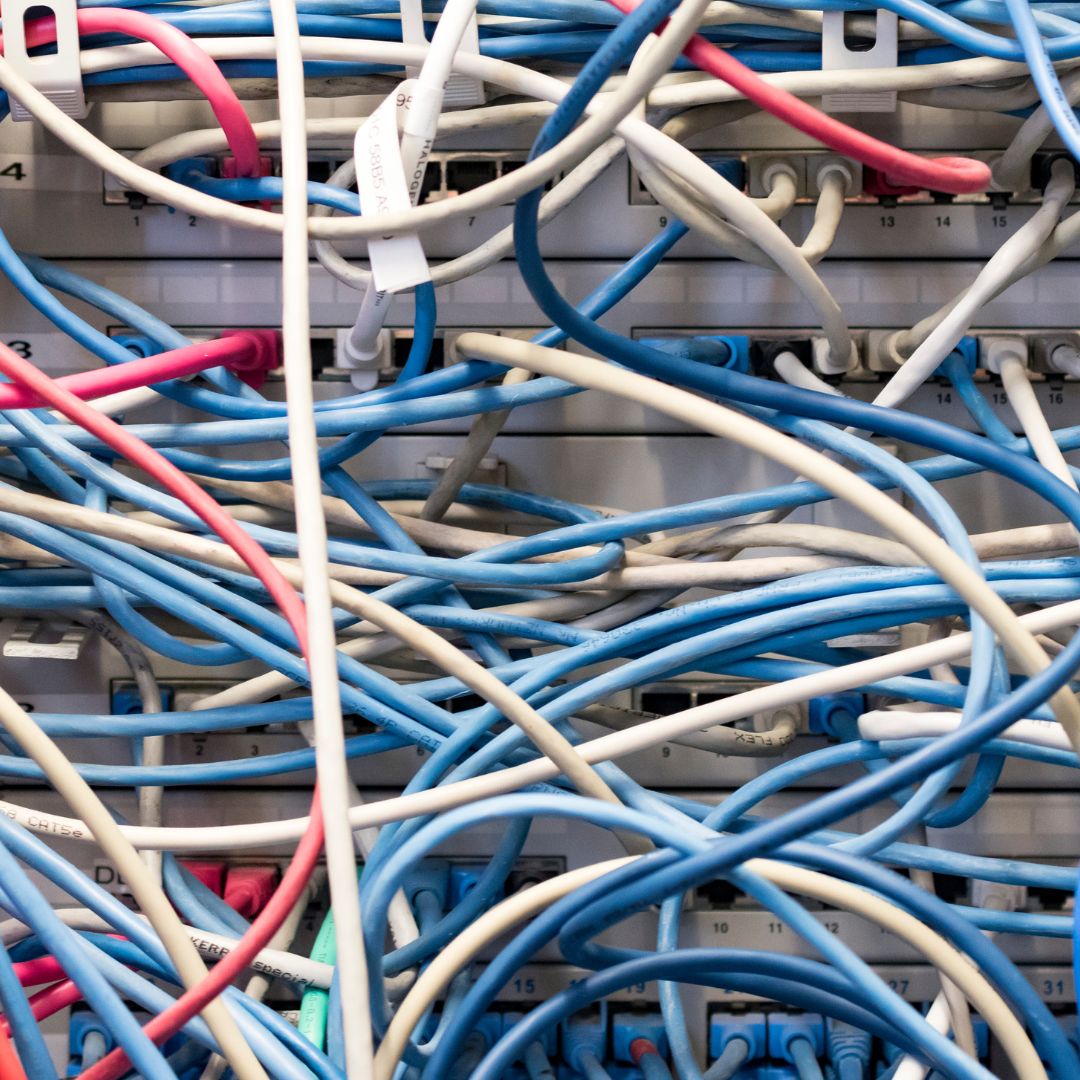

Snapshots to Success – Designs, Installations & Innovation

Explore real-world images, technical diagrams, and on-site application visuals of our Armoured Cables. See construction detail, core types, installation use, and armored layering in high resolution to guide purchase decisions.

FAQs – What Customers Ask Most !

Get expert answers to common questions on Armoured Cables. Learn about compliance, material choice, installation best practices, and performance in government and industrial projects.

What are Armoured Cables used for in infrastructure projects?

Armoured Cables are used in high-load, underground, or outdoor electrical systems to protect against mechanical damage, moisture, and corrosion.

Are Triveni's Armoured Cables ISI and BIS certified?

Yes, our Armoured Cables are ISI-marked and comply with BIS standards like IS 1554 & IS 7098 for reliable public and private sector deployment.

Which is better – aluminium or copper core in armoured cables?

Copper cores offer higher conductivity, while aluminium is lighter and cost-effective. Triveni provides both to suit specific project needs.

Are these cables suitable for solar power plants?

Absolutely. Triveni’s Armoured Cables are MNRE-ready and ideal for underground power transmission in solar EPC projects.

What is the voltage rating of these armoured cables?

Voltage grades range from 1.1 kV to 6.6 kV depending on the conductor size and insulation type

Can Armoured Cables be used in flood-prone areas?

Yes, with PVC/XLPE insulation and galvanized armour, our cables are well-suited for flood zones and moist environments.

Do you offer PWD-compliant Armoured Cables for government tenders?

Yes, Triveni’s cables meet all technical and documentation requirements for PWD and ULB tender submissions.

What kind of mechanical protection does the armour provide?

Galvanized wire or strip armour provides strong resistance against physical cuts, rodents, and environmental wear.

Is customization available for length or sheath type?

Yes, lengths, outer sheath material (FR/FRLS), and core count can be customized as per order.

How is installation handled for these cables?

We provide installation guides and offer support for trench layout, cable routing, and jointing instructions as per site conditions.

Related Products

Discover related products that complement your needs – durable, efficient, and affordable solutions for lighting, solar, and infrastructure projects.

DWC Pipe (Double Wall Corrugated Pipe)

High strength, durability, lightweight, easy installation, chemical resistance, UV resistant, high ring stiffness, long service life, non-toxic, smooth inner surface.

HDPE Pipe (High-Density Polyethylene Pipe)

High strength, flexibility, corrosion resistance, lightweight, long service life, UV resistant, chemical resistance, leak-proof, impact resistant, smooth inner surface.