If you’re shortlisting poles for city streets, campuses, industrial estates, or solar-ready corridors, octagonal street light poles deliver high strength, clean aesthetics, and dependable corrosion resistance when proper steel grades and hot-dip galvanizing are specified. Typical working heights in India range from 6 m to 12 m, with base plates, anchor bolts, access doors, and outreach arms sized to wind and fixture loads. Ask vendors to specify steel grade (e.g., S355J0/S235JR), galvanizing to IS/EN standards with average micron thickness, design wind speed rating, and to share a BoQ with drawings.

What is an Octagonal Street Light Poles?

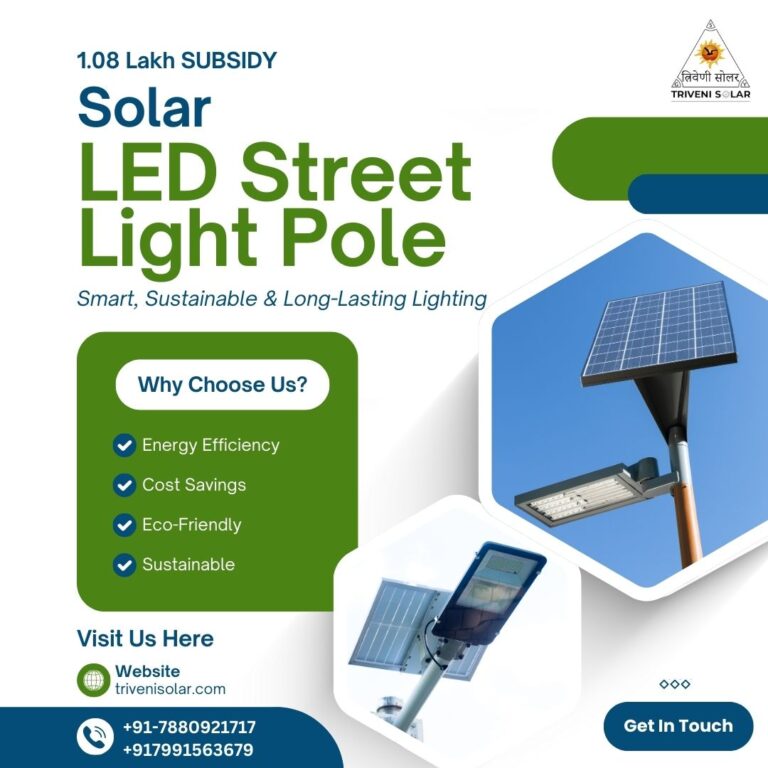

An octagonal pole is a tapered, eight-sided, welded steel structure used to mount luminaires, banners, CCTV or solar hardware. The form factor improves structural stability and looks premium in modern streetscapes. Globally, municipalities and OEMs recognize the octagonal form as a standard choice for higher wind areas and urban corridors—one reason you’ll often see it specified in public works and city manuals.

Key advantages:

- High strength-to-weight with tapered geometry.

- Simplified mounting for single/double arm brackets, CCTV, and signage.

- Clean look vs. lattice/utility structures, suitable for boulevards and campuses.

- Readily hot-dip galvanized for long service life in Indian climates.

Octagonal Street Light Poles Materials & Standards that matter

Steel grades (and where they fit)

Reputable Indian and global brochures specify structural grades such as S355J0 (EN 10025) for higher-strength poles; some product lines use S235JR for certain sizes and applications. The choice affects wall thickness and allowable loads. Insist the vendor declares the steel grade in writing on drawings/BoQ.

Hot-dip galvanizing (IS/EN)

In India, public-sector specs frequently mandate hot-dip galvanizing with an average coating thickness around ~65 μm (and inspection as per relevant IS/EN standards). Many OEM brochures also reference EN ISO 1461 (or equivalent) for galvanizing, which is widely accepted. Ask for galvanizing certificates and a clear statement of minimum average microns.

Wind design inputs

OEM literature commonly lists design wind speeds from ~160 to ~300 km/h depending on model, height, and site exposure. The practical takeaway: your height + outreach + luminaire area must be matched to a stated wind rating in the datasheet. For projects in coastal or cyclone-prone zones, request a calculated check and consider stepping up to higher steel grades or thicker sections.

Octagonal Street Light Poles Size & Application Matrix

Below is a simplified, India-oriented matrix you can use to frame a first pass. Always verify against vendor datasheets and wind loading.

| Typical Height | Where it fits | Common Arm Options | Notes |

|---|---|---|---|

| 6–7 m | Campus lanes, housing societies, internal roads | 0.5–1.0 m single arm | Cost-efficient, minimal visual impact. |

| 8–9 m | City streets, collectors, tech parks | 1.0–1.5 m single/double | India’s workhorse range; balance of throw and mast height. |

| 10–12 m | Arterials, industrial roads, wide ROWs | 1.5–2.0 m single/double | Heavier arms, higher wind moment; check base plate & bolts. |

Common OEM height ranges for octagonal poles fall between 3 and 12 m, with tables providing top/bottom diameters, base plates, anchor bolt patterns, and door sizes. Ask your vendor for the exact dimensional chart for the height you select.

Octagonal vs Tubular vs Conical—which should you choose?

- Octagonal: excellent stability in windy sites, easy to accessorize, good aesthetics. Often the default for urban and highway lighting.

- Round conical: widespread and elegant; may suit parks, walkways, and decorative zones.

- Swaged tubular: economical and common for legacy installs, but typically lower perceived aesthetics and sometimes heavier for equivalent stiffness.

Octagonal Street Light Poles Foundations, Base Plates & Anchor Bolts

The base plate connects the tapered shaft to a concrete foundation via anchor bolts and a template. Datasheets typically list plate size and thickness (e.g., 16–25 mm depending on height), bolt circle, and bolt size. Good brochures also mention door openings, internal cable routing, and service junctions. Your BoQ should call up:

- Base plate dimensions & grade (e.g., plate steel conforming to structural standards).

- Anchor bolt diameter, length, and grade; template & setting methodology.

- Door size and lock; internal earthing; feeder cable path.

- Galvanized surfaces, touch-up rules, and leveling shims/grouting.

Octagonal Street Light Poles Typical BoQ / Schedule of Items

- Item: Supply & erection of [height] m Octagonal Street Light Pole, tapered, with single/double outreach arm [length] m; hot-dip galvanized to average ≥65 μm (verify relevant IS/EN clauses). Shaft in [steel grade—e.g., S355J0/S235JR]; base plate [size × thickness] with [n] × [Ø] mm anchor bolts and template.

- Accessories: Access door with lock, internal cable, earthing stud, and terminal block.

- Erection: Foundation excavation, concreting [grade], jigs/templates, bolt setting, leveling, grouting, raising & plumbing, torqueing to spec, as-built handover.

- Docs: Mill test certificates, galvanizing test report, QA/QC plan, as-built drawings, and O&M.

Price drivers in India

Expect quotes to vary by steel grade & thickness, height & outreach, wind rating, galvanizing thickness, and foundation scope. Marketplace listings show wide ranges (e.g., ₹4,000–₹14,500 for 6–10 m depending on spec and scope), but enterprise projects trend higher with stricter QA and civil works. Always seek like-for-like specs when evaluating multiple vendors.

QA you should insist on

Top Indian OEMs highlight in-house galvanizing, wind testing, and documented QA. Ask for:

- Material test certificates (steel grade confirmation).

- Galvanizing certificates (standard & average microns).

- Dimensional check records, weld procedure qualifications.

- Optional third-party tests or wind tunnel/structural validations.

Case uses & add-ons

- Urban streets & arterials: 8–12 m, decorative single/double arms.

- Industrial corridors & ports: higher wind ratings, thicker sections.

- CCTV/smart city: camera mounting spigots, internal conduit.

- Solar-ready: bracketry and cable routing aligned with solar luminaires—a Triveni Solar strength as an integrated provider.

Why Triveni Solar (trusted project partner)

As an Indian renewable and lighting integrator, triveni solar combines pole supply, luminaire engineering, and solar know-how, simplifying procurement. We help you:

- Select the right height/outreach by road class & spacing.

- Match wind rating to site exposure.

- Bundle foundations, anchor bolts, and installation under one SLA.

- Close BoQ gaps so tenders are spec-tight and vendor-neutral.

FAQ

Q1. What height should I choose?

Start from road width and illuminance goals; 8–10 m suits many urban corridors, and 10–12 m for wider arterials or industrial estates. Cross-check OEM tables.

Q2. Which steel grade is right?

For higher heights/winds, S355J0 is commonly specified; S235JR may be used on smaller poles. Confirm in design calcs.

Q3. How many microns of galvanizing?

Public specs often call for ~65 μm on average; some buyers demand more in coastal zones. Verify standard and QC reports.

Q4. Can octagonal poles take CCTV & banners?

Yes—ensure the additional projected area is included in the wind check and the arm/adapter is rated accordingly.