Certified HDPE Pipes for Water, Sewer and Ducting

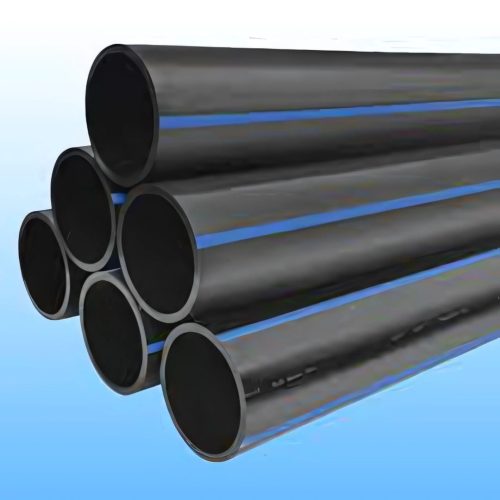

High-quality HDPE Pipes made from PE-63, PE-80, and PE-100 grades, available in 20 mm to 630 mm diameter and PN 2.5 to PN 16. Ideal for water supply, drainage, and cable ducting. ISI certified, BIS-compliant, UV-resistant, leak-proof, and approved by PWD, ULB, and government tender agencies.

HDPE Pipes – Marked High-Density Polyethylene Pipes

Get ISI-marked HDPE Pipes made from high-grade polyethylene for reliable water supply, irrigation, drainage, and cable ducting. Available in various sizes and pressure ratings. UV-resistant, leak-proof, and compliant with BIS, PWD, and ULB project standards.

Specifications – HDPE Pipe (High-Density Polyethylene Pipe)

Parameter | Specification |

|---|---|

| Product Name | HDPE Pipe (High-Density Polyethylene Pipe) |

| Material | HDPE (PE-63 / PE-80 / PE-100) |

| Diameter Range | 20 mm to 630 mm |

| Pressure Rating (PN) | PN 2.5 to PN 16 |

| Length | 6 m / 12 m or coil form (customizable) |

| Color | Black with Blue Stripes |

| Standard Compliance | IS 4984:2016 / ISO 4427 |

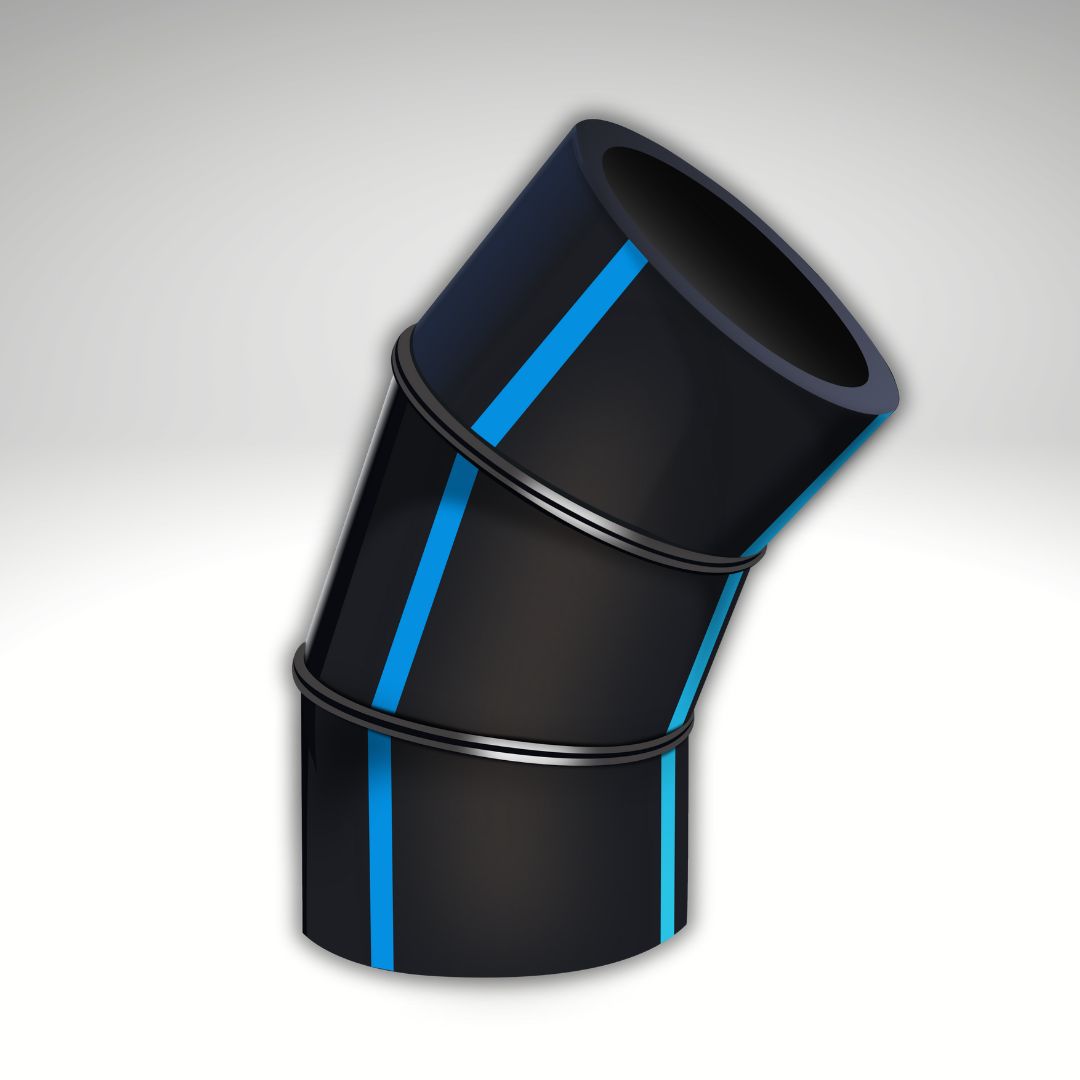

| Joint Type | Butt Fusion / Electro Fusion / Flange Joint |

| UV Resistance | Yes |

| Application | Water Supply, Sewerage, Irrigation, Cable Ducting |

| Certification | ISI Certified, BIS Compliant, PWD Approved |

Use Cases Across Industries & Projects

HDPE Pipes are widely used across government and industrial sectors for water supply, sewerage, and cable ducting. ISI certified and durable, they are suitable for PWD, irrigation, telecom, and infrastructure development.

Municipal & Government

- PMGSY rural water lines

- Jal Jeevan Mission pipelines

- ULB sewer and drainage networks

- Smart city underground cable ducting

- PWD-approved water supply projects

Commercial & Industrial

- Factory utility piping

- Irrigation and drip networks

- Industrial effluent transport

- Borewell casing for agriculture

- Telecom and OFC cable conduit

Special Use Case

- Electrification projects

- Subsurface drainage systems

- Construction dewatering systems

- Railway signaling and cable ducts

- HDPE ducts for renewable energy sites

Use Cases Across Industries & Projects

Access expert support for HDPE Pipe installation, jointing techniques, routine maintenance, and warranty coverage. Designed for engineers, contractors, and procurement heads ensuring long-lasting infrastructure delivery.

Installation Guide

- Compatible with Butt Fusion, Electrofusion & Compression jointing

- Recommended trenching and bedding methods

- Use of end caps to prevent debris ingress during installation

- Thermal expansion and pipe alignment guidance

- Safety precautions during welding and handling

Maintenance & Services

- Flushing protocols for debris removal

- UV and chemical-resistant for low-maintenance lifecycle

- Periodic inspection for soil settlement or joint loosening

- Support for leak testing and pressure validation

- Technical team assistance available on request

Warranty & Assurance

- Third-party testing reports available

- Traceable batch coding for accountability

- Triveni quality assurance with every batch

- BIS/ISI certification ensures reliability in public tenders

- Product warranty up to 10 years (subject to use conditions)

Snapshots to Success – Designs, Installations & Innovation

Explore high-resolution images of HDPE pipes used in real infrastructure and utility projects. View cross-sections, installation diagrams, fusion jointing, and ducting layouts to assess quality, durability, and field application.

FAQs – What Customers Ask Most !

Explore top buyer queries on HDPE Pipes including technical specs, installation, pressure ratings, and certifications. Designed to aid procurement teams, engineers, and contractors in informed decision-making.

What are HDPE Pipes used for in infrastructure projects?

HDPE Pipes are used for water supply, sewerage, drainage, cable ducting, and irrigation in municipal, industrial, and agricultural infrastructure.

What pressure ratings are available for HDPE Pipes?

Triveni HDPE Pipes are available from PN 2.5 to PN 16, suitable for both low- and high-pressure water or fluid transport systems.

Are your HDPE Pipes ISI certified?

Yes, Triveni HDPE Pipes conform to IS 4984 and IS 14333 and carry ISI markings for use in public sector and institutional projects.

What jointing methods can be used with HDPE Pipes?

Our HDPE Pipes support butt fusion, electrofusion, and mechanical compression fittings for secure and leak-proof connections.

What sizes of HDPE Pipes are available?

We offer HDPE Pipes ranging from 20 mm to 630 mm in diameter, in PE-63, PE-80, and PE-100 grades, as per project requirements.

Can HDPE Pipes be used for telecom ducting?

Yes, HDPE Pipes are widely used as ducts for optical fiber cables and telecom lines due to their flexibility and corrosion resistance.

What color and markings are standard on HDPE Pipes?

Triveni HDPE Pipes are typically black with blue stripes and include ISI/BIS markings along with batch codes and specifications.

Are these pipes suitable for underground installation?

Yes, HDPE Pipes are ideal for underground installation owing to their resistance to soil corrosion, flexibility, and seamless jointing.

Do HDPE Pipes require regular maintenance?

Due to their high chemical and UV resistance, HDPE Pipes require minimal maintenance and are ideal for long-term pipeline systems.

How can I order HDPE Pipes for a government project?

You can contact Triveni's institutional sales team with your BOQ and tender specs. We provide documentation, certifications, and dispatch logistics.

Related Products

Discover related products that complement your needs – durable, efficient, and affordable solutions for lighting, solar, and infrastructure projects.

DWC Pipe (Double Wall Corrugated Pipe)

High strength, durability, lightweight, easy installation, chemical resistance, UV resistant, high ring stiffness, long service life, non-toxic, smooth inner surface.

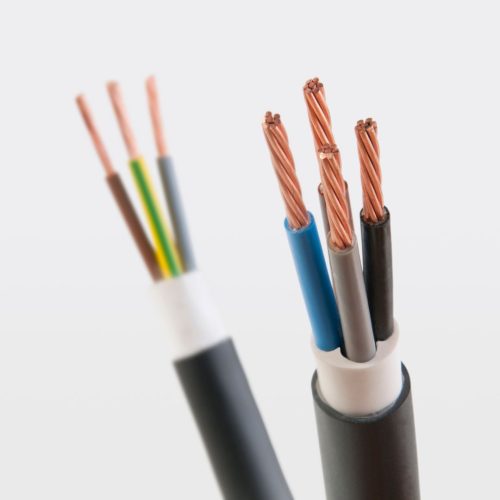

Armoured Cables (Aluminium/Copper Core)

Armoured cable, Aluminium core cable, Copper core armoured cable, XLPE armoured cable, PVC armoured cable, Underground armoured cable.