Looking to partner with a high‑quality OEM in India for your high mast pole? This guide walks you through everything—from manufacturing specs and certifications to cost analysis, innovations, and real‑world procurement tips—so you can make the best decision for your infrastructure project.

Table of Contents

- What is a high mast pole?

- Why India is the Superior Choice for High Mast Pole OEMs

- Manufacturing Specifications You Must Know Before Ordering

- How to Select a Trusted OEM Partner in India

- Cost and Value Analysis That Delivers Massive ROI

- Innovations and Trends Redefining High Mast Poles Today

- Common Mistakes That Could Destroy Your Project Budget

- Frequently Asked Questions

- Conclusion – Move Ahead with Confidence

What is a high mast pole?

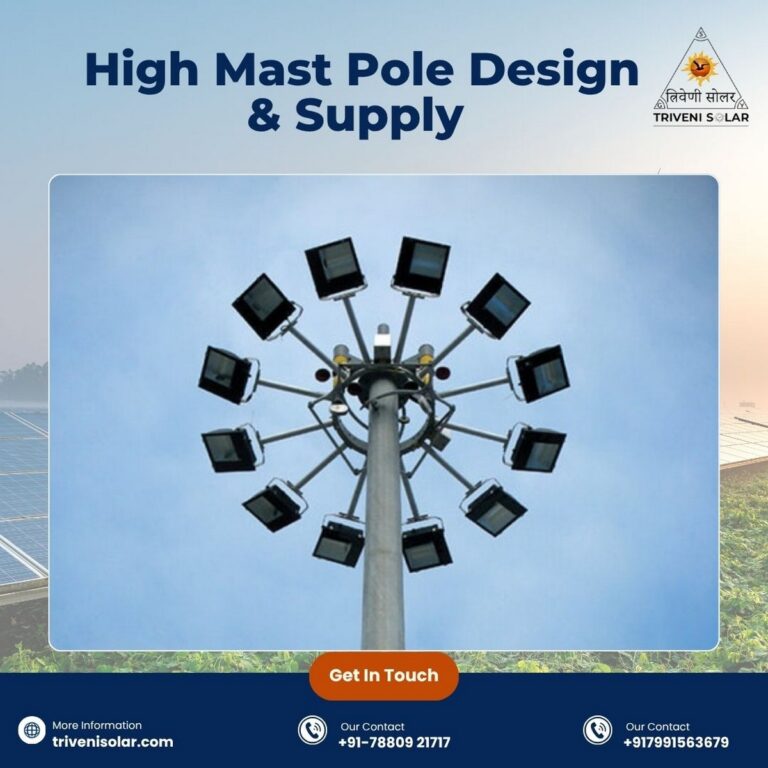

A high‑mast pole is a tall lighting structure designed to illuminate large outdoor areas such as stadiums, ports, highways, industrial zones, and large parking lots. Typically ranging from 10 m to 60 m in height, it radically reduces the number of poles needed while delivering uniform, high‑lux illumination. :contentReference[oaicite:0] {index=0}

Functionally, the pole supports a luminaire ring or multi‑arm cluster, sometimes includes winch systems for lowering the lights, and must be engineered to withstand high wind loads, corrosion, and long service‑life demands.

Why India is the Superior Choice for High Mast Pole OEMs

Choosing an OEM based in India for your high‑mast pole offers several compelling advantages:

- Cost‑effective fabrication thanks to local availability of steel and galvanization facilities.

- Compliance with Indian & international standards—many Indian manufacturers certify to IS 875 wind‑load codes and use hot‑dip galvanization processes. : contentReference[oaicite:2] {index=2}

- Export‑ready engineering—many Indian OEMs serve aerospace, stadium, and highway sectors and can customize for global wind/safety zones.

- Supply chain strength—proximity to upstream steel vendors (e.g., SAIL, TATA Steel) ensures quality control and traceability. :contentReference[oaicite:5] {index=5}

- Maintenance & lifecycle support—local fabrication means easier logistics, spares, site service, and shorter delivery lead times.

For infrastructure decision-makers in India or working with Indian suppliers abroad, this makes Indian OEMs an excellent choice.

Manufacturing Specifications You Must Know Before Ordering

Height, Shape & Structural Design

High mast poles typically fall in the 10‑60 m range. Indian manufacturers regularly list 12 m–40 m as common. contentReference[oaicite:6] {index=6}

Material, Galvanisation & Corrosion Resistance

Commonly made of mild steel plates (yield strength 355 N/mm² or IS2062 E350), welded into tapered polygonal or octagonal shapes. Example: one manufacturer uses internal and external hot‑dip galvanization with a thickness of 70‑85 microns for plates. contentReference

Wind Load & Seismic Considerations

Wind‑load design is governed by IS 875 (Part III), and many Indian manufacturers guarantee capacities up to 300 km/h.

Lighting Integration & Accessories

Specifications may include a multi‑arm luminaire ring, routing for trailing cables, a winch and lowering system, aviation lights, door access, earthing, and a lightning finial. These details matter for large‑scale installations.

Typical Specification Comparison Table

| Parameter | Standard Value (Typical Indian OEM) | Importance for Buyer |

|---|---|---|

| Mast Height | 12–60 m | Determines area coverage & number of lights |

| Material Grade | IS 2062 E350 / BS EN 10025 S355 | Strength & fabrication reliability |

| Galvanisation Coating | 70–85 µm + optional PU paint | Corrosion resistance & lifespan |

| Wind Load Withstanding | Up to 300 km/h | Safety & compliance, especially coastal/industrial |

| Design Life | 25 years minimum | Lifecycle cost & ROI planning |

How to Select a Trusted High Mast Pole OEM Partner in India

Selecting the right OEM involves more than comparing quotes. Here are key criteria:

Certifications & Quality Assurance

Ensure the manufacturer holds ISO 9001 or equivalent, has export readiness, and has third‑party testing (wind tunnel, structural analysis). Example: a leading manufacturer lists certified software and wind tunnel tests.

Manufacturing Capacity & Lead Time

Check annual production capacity (e.g., 10,000 lighting masts per year) and whether they can meet your schedule. Overseas procurement demands reliable lead times.

High Mast Pole Design Flexibility & Customisation

Your project may need non‑standard height, a winch system, solar integration, a customized base plate, or coaxing imagery. The right OEM will offer bespoke design, not simply catalog items.

After-Sales Support & Maintenance

Ask about spare‑parts support, site services, warranty (at least 1–2 years), and upgrade path (LED retrofit, IoT sensors)—these reduce long‑term risk.

(Location & Logistics Considerations)

When sourcing in India, assess the distance to your site, freight to port or inland, packaging quality, and clearance experience for export if needed.

High Mast Pole Cost and Value Analysis That Delivers Massive ROI

Understanding the true cost of high‑mast poles is critical for infrastructure decision‑makers. Here’s a breakdown:

High Mast Pole Price Breakdown

- Raw material (steel plate) and galvanization dominate cost.

- Fabrication, welding, finishing, and lifting/installation add value.

- Logistics, export duties (if any), and site installation also matter.

Typical Price Range (India)

For example, a 25 m pole from an Indian manufacturer is listed at ~₹ 220,000.

Total Cost of Ownership (TCO) & ROI

A well‑galvanized high‑mast pole with a 25‑year design life reduces maintenance, replacement, and downtime costs compared to cheaper alternatives. Calculate yearly cost = purchase + installation + maintenance divided by design life.

Estimated Cost Comparison Table

| Scenario | Initial Cost | Annual Maintenance | Estimated Lifespan | Approximate Annual Cost |

|---|---|---|---|---|

| Standard Indian OEM, 30 m height | ₹ 250,000 | ₹ 5,000 | 25 yrs | ≈ ₹ 12,200/yr |

| Low‑cost import alternative | ₹ 200,000 | ₹ 20,000 | 15 yrs | ≈ ₹ 14,667/yr |

Thus, a higher upfront cost from a trusted OEM often translates into lower annual cost and fewer replacements—a “massive ROI” for large projects.

Innovations and Trends Redefining High Mast Pole Today

Modern high‑mast pole solutions are evolving rapidly. Key trends include:

- Smart integration: IoT sensors, energy monitoring, and remote lowering systems.

- Solar/hybrid poles: Combining solar panels and batteries with high‑mast lighting for remote locations.

- Modular design: Segmented transport and installation for quick deployment.

- Sustainability: Use of zinc‑rich coatings, recyclable materials, and reduced waste fabrication.

By working with an innovative OEM, you gain future-proof benefits and enhance long-term value.

Common Mistakes That Could Destroy Your Project Budget

Here are pitfalls to avoid when procuring high‑mast poles:

- Ignoring wind‑load requirements: Underspecification can lead to failure or costly rework.

- Choosing the lowest bidder blindly: Compromised coatings or fabrication will raise maintenance costs or shorten lifespan.

- Neglecting logistics & installation: Heavily fabricated poles that don’t account for transport or site conditions.

- No long‑term maintenance plan: Without support, downtime and replacement costs escalate.

A well‑informed procurement strategy avoids these and ensures your infrastructure investment is sound.

Frequently Asked Questions

What height is considered “high mast”?

In the Indian infrastructure context, poles above ~10–12 m are often called high‑mast. Many OEMs list 12 m–60 m ranges.

Can an OEM customize the design for my project?

Yes, Indian high‑mast OEMs often provide bespoke heights, winch systems, solar integration, and tailored coatings—provided your specification is clear and design loads defined upfront.

What certifications should a high mast pole manufacturer have?

Look for ISO 9001 quality systems, evidence of wind‑load testing (IS 875 or equivalent), galvanization standards, and export‑readiness. OEMs specifying “up to 300 km/h” indicate strong engineering.

What is the typical lifespan of a galvanized high mast pole?

Standard design life for well‑manufactured high mast poles is 25 years or more, assuming quality fabrication, galvanization, and maintenance are in place

Conclusion – Move Ahead with Confidence

Selecting the right high‑mast pole OEM in India means investing wisely in your infrastructure future. By confirming structural specs, evaluating manufacturing processes, understanding full cost implications, and partnering with an OEM who delivers support beyond sale, you secure durability, performance, and value.

When you’re ready to take the next step in your lighting‑ or infrastructure‑project, consider contacting us at Triveni Solar for expert guidance, tailored manufacturing, and full‑spectrum support. Reach out today to discuss your high mast pole requirement and partner with a trusted OEM for India and beyond.