MNRE-Approved Solar Structure Base Plate – Galvanized and Certified

Triveni Solar offers MNRE-approved, ISI-marked Solar Structure Base Plates made from heavy-duty galvanized steel. Ideal for ULB, PWD, and EPC solar projects, our BIS-certified base plates ensure structural stability and compliance for rooftop, ground-mount, and industrial solar installations across India.

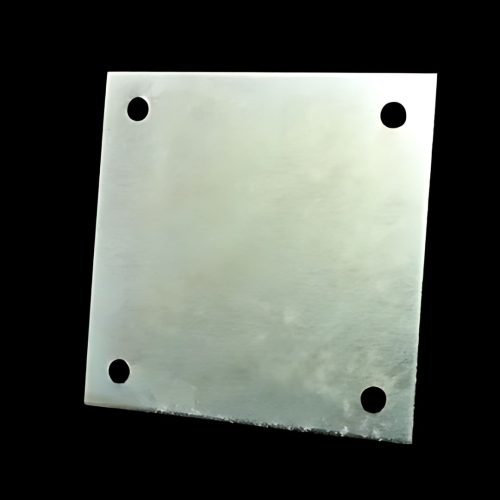

Heavy-Duty Galvanized Solar Structure Base Plate

Explore our BIS-certified Galvanized Solar Structure Base Plate, designed for maximum load-bearing and corrosion resistance. Ideal for secure solar mounting applications, it ensures long-term stability across varied installations. Available in multiple sizes and thicknesses to suit your project needs.

Specifications – Solar Structure Base Plate

Parameter | Specification |

|---|---|

| Product Type | Solar Structure Base Plate |

| Material | Mild Steel (MS) |

| Surface Finish | Hot Dip Galvanized |

| Galvanization Thickness | 80–100 Microns |

| Plate Dimensions | 150mm x 150mm to 300mm x 300mm |

| Plate Thickness | 6 mm / 8 mm / 10 mm |

| Hole Configuration | 4 Holes (as per standard mounting layout) |

| Bolt Hole Diameter | 16 mm – 24 mm |

| Load Capacity | Up to 2 Tons (Varies by configuration) |

| Compliance & Certification | BIS / ISI / MNRE Guidelines |

Use Cases Across Industries & Projects

Discover how Solar Structure Base Plates support critical solar infrastructure across government, commercial, and specialized projects. Designed for durability and code compliance, these plates meet EPC, MNRE, and ULB tender requirements nationwide.

Municipal & Government

- PWD and ULB solar street light installations

- Solar panel mounting in smart city projects

- MNRE-compliant installations under state solar missions

- Rooftop systems on government buildings and PSUs

- Public park and parking solar canopy structures

Commercial & Industrial

- Utility-scale solar farms and microgrids

- Off-grid power setups for logistics hubs

- Warehouse rooftop solar support structures

- Solar parking shelters in commercial complexes

- Ground-mount solar projects for manufacturing plants

Special Use Case

- Solar-powered EV charging stations

- Remote telecom tower solar integration

- Solarized rural electrification and mini-grids

- Defence and border area solar infrastructure

- Solar water pump support systems in agriculture

Use Cases Across Industries & Projects

Access full lifecycle support for Solar Structure Base Plates—covering installation, service schedules, warranty terms, and structural compliance. Designed for EPCs, PWD contractors, and solar installers seeking reliable mounting components.

Installation Guide

- Bolt pattern alignment instructions

- Torque settings for anchoring bolts

- Pre-installation surface prep checklist

- Recommended foundation dimensions

- Galvanization preservation tips during setup

Maintenance & Services

- On-site plate replacement services

- Corrosion treatment for coastal projects

- Galvanized surface inspection frequency

- Bolt tightening schedule post-installation

- Annual load-bearing revalidation checklist

Warranty & Assurance

- BIS/ISI certification compliance

- Product traceability with QR code labels

- Documentation for MNRE tender eligibility

- Replacement coverage for manufacturing defects

- 5–10 year anti-corrosion warranty options

Snapshots to Success – Designs, Installations & Innovation

View detailed images and technical diagrams of Solar Structure Base Plates in real-world use. Explore installation examples, 3D CAD drawings, and close-ups to evaluate material strength, bolt patterns, and compatibility for your next solar project.

FAQs – What Customers Ask Most !

Get answers to the most asked questions about Solar Structure Base Plates. Learn about specifications, standards, compatibility, and compliance to ensure the right fit for your solar infrastructure or EPC project requirements.

Related Products

Discover related products that complement your needs – durable, efficient, and affordable solutions for lighting, solar, and infrastructure projects.

Solar Panel Clamps (End and Mid)

Anodized, rustproof, durable, corrosion-resistant, lightweight, secure, precision-fit, high-strength, weatherproof, UV-resistant, aluminum-based.

Anchor Bolts for Solar Mounting

High-tensile, galvanized, corrosion-resistant, rustproof, durable, threaded, precision-engineered, load-bearing, weatherproof, vibration-resistant, long-lasting.

Solar Fastener Kits and Hardware

Corrosion-resistant, galvanized, high-tensile, rustproof, precision-fit, durable, weatherproof, ISO-certified, stainless, vibration-proof, easy-installation.