Certified Steel Tubes and Pipes (MS/GI) for Infrastructure

Explore high-quality MS and GI Steel Tubes and Pipes compliant with IS:1239 and IS:1161 standards. Ideal for structural frameworks, pipelines, fencing, solar mounting, and utility ducts. Available in round, square, and rectangular sections with galvanization options.

Steel Tubes and Pipes (MS/GI) – IS:1239 & IS:1161 Compliant Supply

Get ISI-certified Mild Steel (MS) and Galvanized Iron (GI) Tubes and Pipes for structural, industrial, and utility projects. Compliant with IS:1239 and IS:1161 standards. Available in round, square, and rectangular sections for public and private infrastructure.

Specifications – Steel Tubes and Pipes (MS / GI)

Parameter | Specification |

|---|---|

| Product Name | Steel Tubes and Pipes (MS/GI) |

| Types Available | MS Black, GI (Pre-Galv / Hot Dip Galv) |

| Cross-Section | Round / Square / Rectangular |

| Size Range | 15 mm NB to 300 mm NB |

| Wall Thickness | 1.5 mm to 10 mm |

| Material Standard | IS:1239, IS:1161, IS:3589 |

| Surface Finish | Black / Galvanized (Pre or Hot Dip) |

| Galvanization Thickness | 40–80 Microns (Avg.) |

| Length | 6 Meters (Standard) / Custom on request |

| End Finish | Plain / Beveled / Threaded |

| Applications | Structures, Water Lines, Fencing, Solar Mounts |

| Certifications | ISI, BIS, PWD, Third-Party Test Certificates |

Use Cases Across Industries & Projects

Explore the versatile applications of Steel Tubes and Pipes (MS/GI) across infrastructure, utility, and industrial projects. Available in multiple sizes and finishes to support both load-bearing and fluid-carrying systems.

Municipal & Government

- PWD pipeline installations

- Smart city utility frameworks

- Water distribution and drainage

- Electrification support structures

- Streetlight and signage pole fabrication

Commercial & Industrial

- Solar mounting structures

- HVAC and fire safety lines

- Plant piping and conveyors

- Fencing and boundary frameworks

- Steel scaffolding and construction

Special Use Case

- Bridge utility conduits

- Airport lighting supports

- Railway and metro ducting

- Telecommunications tower frames

- Rural water supply and irrigation

Use Cases Across Industries & Projects

Access full technical support and documentation for Steel Tubes and Pipes (MS/GI), including quality certifications, testing parameters, and installation recommendations. Perfect for tender documentation and engineering assessments.

Installation Guide

- Pipe threading and jointing methods

- Pressure and leakage test protocols

- Galvanization touch-up instructions

- Proper storage and handling to avoid rust

- Welding and surface re-coating procedures

Maintenance & Services

- Pipe replacement guidelines

- Periodic corrosion inspections

- Recoating and anti-rust treatment

- Flow testing and blockage removal

- Pressure testing for fluid-carrying pipes

Warranty & Assurance

- ISI/BIS certification with batch traceability

- Third-party lab testing on request

- Galvanization warranty (Hot Dip GI)

- Dimensional and weight tolerance guarantee

- Customer service for bulk orders and tenders

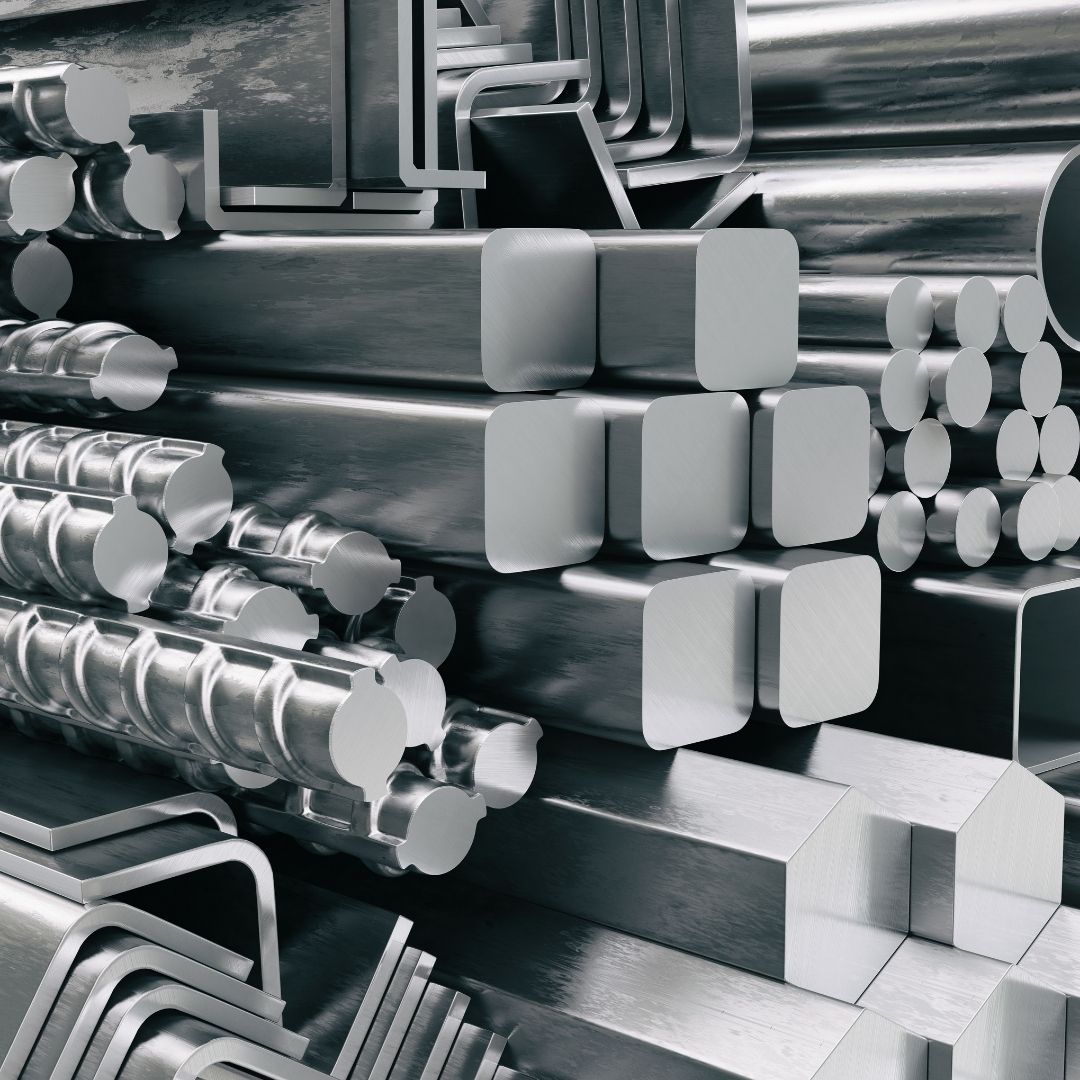

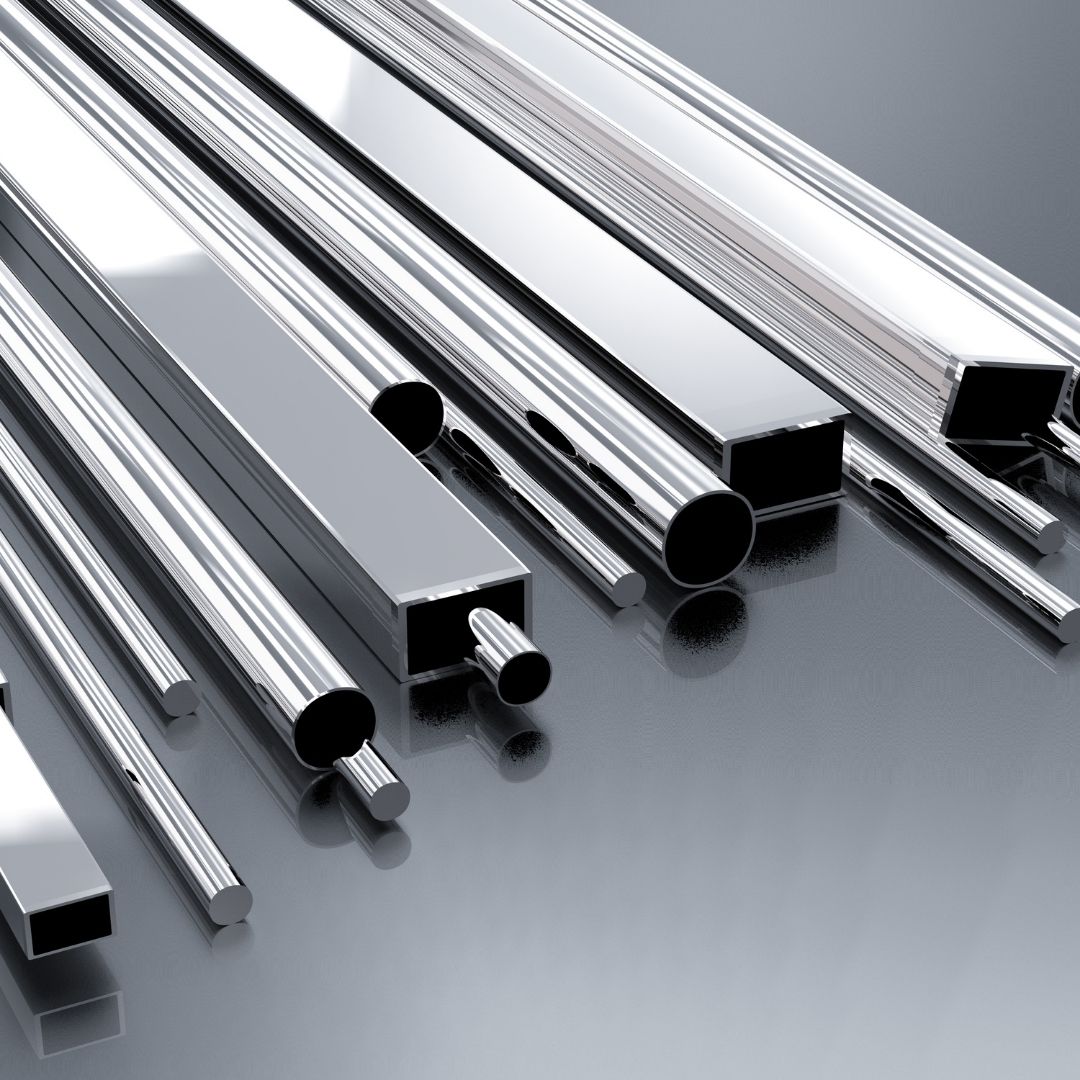

Snapshots to Success – Designs, Installations & Innovation

Browse visuals showcasing Steel Tubes and Pipes (MS/GI) in various shapes, sizes, and finish options. Includes application photos, cut-section diagrams, surface coatings, and third-party test reports for EPC teams and contractors.

FAQs – What Customers Ask Most !

Explore frequently asked questions about Steel Tubes and Pipes (MS/GI). From sizes and coatings to standards and applications, this FAQ section helps buyers, engineers, and contractors make informed procurement decisions.

What are the available types of Steel Tubes and Pipes (MS/GI)?

We offer MS Black, Pre-Galvanized, and Hot Dip Galvanized pipes in round, square, and rectangular sections.

Which standards do your pipes comply with?

Our pipes are manufactured as per IS:1239, IS:1161, and IS:3589 standards, with ISI and BIS certification.

Are custom lengths or coatings available?

Yes, we provide pipes in standard 6-meter lengths and custom sizes with options for pre or hot-dip galvanization.

What is the average galvanization thickness?

Hot-dip GI pipes are coated with an average of 40–80 microns as per IS:2629 guidelines for long-term corrosion resistance.

Can these pipes be used in water supply lines?

Yes, GI pipes are widely used in plumbing, irrigation, and water distribution systems, especially in government projects.

Do the pipes support welding and threading?

Absolutely. Our pipes can be welded or threaded depending on project requirements, and are supplied with appropriate end finishes.

Do you provide test certificates?

Yes, third-party test certificates are provided for mechanical, chemical, and galvanization tests on request.

Are these pipes suitable for structural use?

Yes, MS pipes are ideal for scaffolding, frames, supports, solar structures, and light structural work.

How are the pipes packed and shipped?

Pipes are bundled with steel straps, protected against surface damage, and loaded as per transportation standards.

Can I order in bulk for government tenders?

Yes, we specialize in fulfilling bulk orders for PWD, ULB, Jal Nigam, and other public sector procurement schemes.